Sludge2Fuel

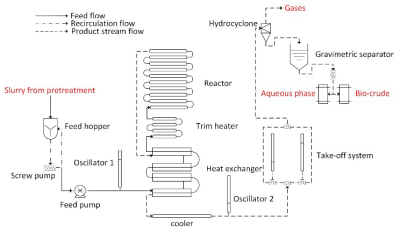

The objective of Sluge2Fuel is to demonstrate the world’s first full scale integration of a modular Hydro Thermal Liquefaction (HTL) unit in a modern Wastewater Treatment Plant (WWTP) and to validate the potential for full scale upgrading of the produced biocrude using green hydrogen. The project will cover the full value chain from wastewater sludge to transport fuel and will validate the vast potential as a commercially and environmental attractive technology in the energy sector.

Milestones:

M1: Integration of HTL and Municipal Wastewater Plant. August 2022

M2: Design and Construction of Package HTL Unit. November 2021

M3: Ready for Operation Package HTL Unit. October 2022

M4: HTL Process Optimization. September 2023

M5: Bio-Crude Logistic & Processing. December 2023

M6: Technoeconomic and life cycle. November 2023

CM1: Communications and Dissemination. February 2023

CM2: Communications and Dissemination. May 2023

The Project is a 3-year demonstration project on integrated Municipal wastewater sludge conversion via a modular Hydro Thermal Liquefaction (HTL) package unit and upgrading of bio-Crude in an Oil Refinery to green fuels in Co-Processing mode. The project covers the full value chain.

The project covers the below Work Packages (WP) in an activity plan:

WP1: Management and Administration. Regular steering meetings. Semi-annual financial statements status reports to EUDP and final project report.

WP2: Integration of HTL and Wastewater Treatment at the FRSE Municipal wastewater Treatment plant

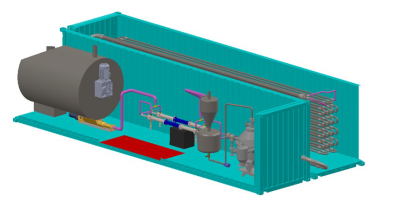

WP3: Design Construction and Commissioning of an HTL modular plant.

WP4: Process Optimization and demonstration runs

WP5: Bio-Crude logistics & Processing

WP6: Final system evaluation

WP7: Communication and dissemination

Above activities are embedded in an overall Project plan. Initially work results in the laboratory are implemented in a modular package unit design and construction at the Municipal Wastewater Plant site. The plant is commissioned and initial optimization runs are performed. The produced bio-Oil is transported by truck to the Refinery and Co-Processed in the existing units to final products. During the first trials products are field tested or tested at the Alfa Laval motor test Centre.

The Project is completed by communicating a series of reports and publications together with a Life Cycle Report (LCA Report) and a final Techno-Economic Report.

Key figures

Category

Participants

| Partner | Subsidy | Auto financing |

|---|---|---|

| Crossbridge Energy A/S | 5,66 mio. DKK | 8,46 mio. DKK |

| Fredericia spildevand og energi A/S | 1,92 mio. DKK | 2,89 mio. DKK |

| KRÜGER A/S | 0,54 mio. DKK | 0,81 mio. DKK |

| Bio2Oil ApS | 4,16 mio. DKK | 2,77 mio. DKK |

| Aarhus Universitet | 7,13 mio. DKK | 0,79 mio. DKK |

Contact

Egeskovvej 265,

7000 Fredericia

Tlf.: 22205638