Udvikling af anlæg til gasbåren flashpyrolyse i multikanal-reaktor med energioverskud

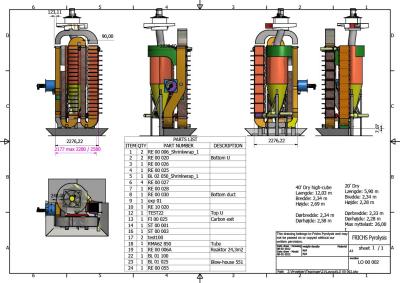

The purpose of the project is thus to develop a full-scale flash pyrolysis plant with a capacity of 15 tons of biomass per day. The plant will be developed in continuation of the reactor patent we have obtained and the experience we have gained over the past 10 years or so with the development of gas-borne flash pyrolysis. We have thus developed the model for a reactor that handles biomass in a new way and optimizes both the plant's own capacity and energy surplus. In order to contribute to the future goal of greater spread of pyrolysis, we will build the plant at Springkilde Æg near Horsens. In the project, the plant can be fed with biomass in the form of the fractions chicken manure, straw and manure fibres.

The focal point of the project is the construction of a full-scale flash pyrolysis plant, and the plant will be built on a technical basis in our patented gasborne method. In a multichannel reactor, the plant will reach a capacity for processing 15 tons of biomass per day. The yield from the plant will be gas for energy purposes and biochar with agronomic utility properties, as well as stable carbon capture. The biomass we have in sight is slurry fibres, chicken manure and straw, each of which has its own characteristics in both the mechanical handling in the plant as well as in the biochar and gas produced. The project is thus divided into three main phases: 1. Pre-treatment of biomass. 2 Pyrolysis – and 3. Validation of biochar and gas, including application. The consortium of the project is composed of actors representing this entire value chain.

The project will be supported by the knowledge we have gained over the past 10 years in the construction of a pilot plant for flash pyrolysis, which differs by operating at higher temperatures – more than 800 degrees Celsius. We can thus incorporate the necessary knowledge on a wide range of crucial parameters in the finished plant. At the same time, the project consists of a group of partners, each of whom offers relevant and significant competencies. From the University of Southern Denmark, the project is provided with measurement methods for validating the plant's yield fractions with a view to optimal societal utilization. In the project, Lykke Smeden will develop an injector that is designed in relation to the application of biochar on dust form, and this will be tested in use in the fields at Havndal at Lisbjerregaard.

Key figures

Category

Participants

| Partner | Subsidy | Auto financing |

|---|---|---|

| Frichs Pyrolysis ApS | 11,97 mio. DKK | 7,98 mio. DKK |

| SPRINGKILDE ÆG P/S | 2,48 mio. DKK | 1,65 mio. DKK |

| LYKKE SMEDEN A/S | 1,20 mio. DKK | 0,80 mio. DKK |

| Lisbjerregaard | 0,62 mio. DKK | 0,41 mio. DKK |

| Syddansk Universitet | 2,32 mio. DKK | 0,26 mio. DKK |

Contact

Adresse: Sverigesvej 14, 8700 Horsens

Tlf.: 40367165

Hjemmeside: www.frichs-pyrolysis.dk